What is a Check Valve?

A check valve ensures single directional flow of either liquid or gas

As a specialist supplier of miniature components, The West Group product portfolio contains a comprehensive range of check valve options. Some of these components can be used as Pressure Relief Valves. In most cases, the valve operation is unaffected by orientation.

Our Check Valve types include Duckbill, Diaphragm (Floating Disc) and Poppet

The West Group strength lies in our ability to support customers and manufacturers supplying into the medical and scientific markets. We provide many specification and material options specifically designed to meet the standards and compliances required by the healthcare industry.

How does a Check Valve work?

Depending upon the type of Check Valve chosen, the operation of the valve differs from type to type.

Duckbill types rely on pressure opening to allow flow. The design of the Duckbill is contoured to ensure at rest the orifice is forced shut.

Floating Disk and Diaphragm types rely upon a membrane sealing against a surface in the flow path with enough stiction to overcome any back flow pressure that may exist in the system. The membrane shifts within the housing as the forward pressure increases until it is greater than the back flow pressure. When this differential occurs, the valve opens.

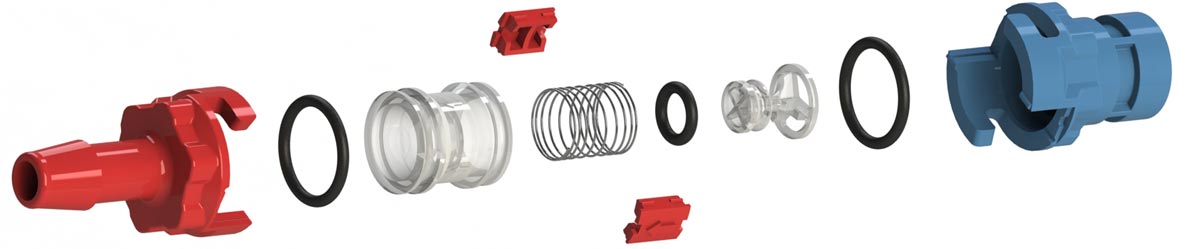

Poppet types generally utilise a spring to replicate the back flow pressure and opens when the forward pressure overcomes the spring force. The term cracking pressure is given to this action.

An advantage of this type of valve design are the low cracking pressures that can be achieved. Small differentials in forward and back flow pressures can be accompanied. The minimum cracking pressure check valve we offer is 0.1 psi.

When the valve is fully open, flow in one direction is relatively unrestricted. When closed, the valve should not exhibit any flow.

Check Valve Specification Options

Duckbill Check Valve

- Valve Body Material:Acrylic Nylon, polycarbonate, Polypropylene, PVDF

- Seal Material: Silicone

- Valve Connections: 1/8 and 3/16 Barb configurations

Diaphragm

- Valve Body Material: Radiation Stable Polycarbonate, PVDF, Acetal, Acrylic, Nylon, Polypropylene

- Seal Material: Celcon, Silicone USP Class VI, EPDM, Viton, FDA Viton, Kalrez

- Valve Connections:.170 Barb, 1/16 Barb, 1/4 Barb, 5/16 Barb, 3/8 Barb, 10-32 UNF Female/ Male, Male Luer/ Female Luer, Male Luer x Barb, Female Luer x Barb, Female Luer x Female Luer. Bondable Check Valves are also available.

- Cracking Pressure: Varied dependent on type

Poppet Check Valve

- Valve Body Material: Nylon, Polypropylene, PVDF, Ultem, ABS, Acrylic, Acetal, Polycarbonate, Stainless Steel, Nickel Plated Brass, Aluminium

- Seal Material: Buna-N, EPDM, Viton, Silicone

- Valve Connections: .170 Barb, 1/16 Barb, 1/4 Barb, 1/8 Barb, 10-32 UNF Male, 4mm OD, 5/64 Barb, 6mm OD, 8mm OD, G1" Female, G1/2"

- Cracking Pressures: Plastic 0-20psi / Metal 0-250psi

Modular Check valve (also Poppet design)

- Valve Body Material: Glass Filled Polypropylene (FDA CFR21 approved)

- Seal Material: Nitrile 60 sh, EPDM 70 sh, Silicone 70 sh, FKM Viton 75 sh

- Valve Connections: Multiple inlet and outlet combinations available: Barb: 1/8", 1/4", 5/16", 3/8", Push-In:4mm, 6mm, 1/4", BSPP Female Thread: 1/8"

- Cracking Pressures: 0.1psi to 8psi