Expanded Cleanroom Capacity

Published date: 12 May 2025

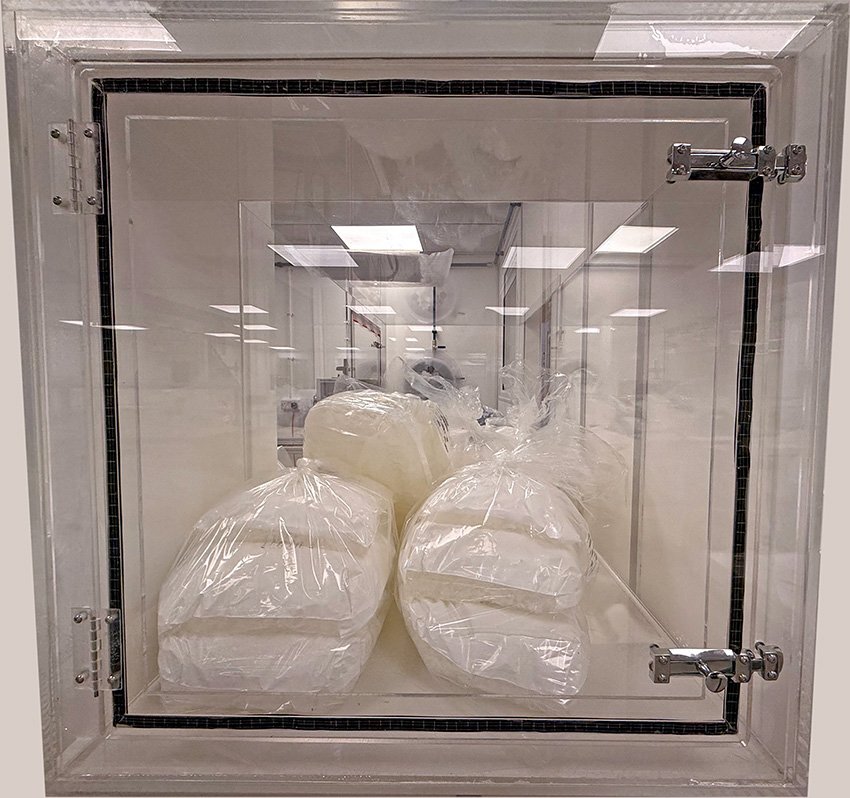

We are thrilled to announce the completion of our newly renovated and expanded Class 8 cleanroom, ensuring we keep pace with demand for sub-assemblies to be built in a clean environment.

Spanning a total of 137.6 m2, this space features a dedicated airlock changing area for controlled entry and a spacious main area. This extra capacity complements our existing Class 7 cleanroom used for those medical devices requiring assembly in even more sterile surroundings.

Many customers require products to be manufactured in such a location to ensure that contaminants such as dust and other particulate matter are eliminated and don’t affect the cleanliness of the component or assembly.

Backed by ISO 9001 and ISO 13485 standards, the quality of the air in our cleanrooms is ensured by annual audits, daily deep-cleaning and bacteria-testing every other month.

Our entire team is focused on maintaining the highest quality output whilst ensuring that all processes and aspects of ISO standards are strictly adhered to, from the outset to completion of a project.

With a scalable operation, we can deliver anything from small production runs to high volume production capability and as such, we are the trusted partner to many large OEMs of medical, scientific and industrial equipment.

Leave us your comment

You need to login to submit a comment. Please click here to log in or register.