The West Group Story - How have we achieved 50 years of success?

Today's success at The West Group began with founder Brian West over 50 years ago

We are always delighted to have the opportunity to catch-up with our founder Brian West. In the following interview, we look back at his years since starting the company as part of our fifty-year celebrations.

Reaching this milestone and taking the time to look at our own company history has been a thoroughly enjoyable experience for today’s West Group team

It was clear when listening to Brian’s detailing of the past, his enthusiasm for miniature fluid control component manufacturing remains. During our interview, he emphasised his ethos of business being about people and sharing success with them along the way.

Our continued growth is very much a result of the foundations Brian put in place all those years ago. We continue a shared approach with our much-expanded teams today.

Interview with our founder Brian West

"always looking to people and the future"

Where it all began …

Brian was born in Purbrook, Hampshire in 1941. On the same day, the largest air raid of World War II was inflicted on the nearby city of Portsmouth. In December of 1941, Prime Minister Winston Churchill visited Portsmouth Dockyard and received the Freedom of the City. To this day, the city of Portsmouth is the only place in the UK to have a road named after Winston Churchill.

In his early years, Brian suffered from tuberculosis and as a result, missed his 11 exam. However, he went on to successfully complete his secondary modern education. With a passion for all sports, Brian represented Hampshire as a schoolboy. He went on to become a part-time professional footballer for Havant and Waterlooville.

Being a proud father encouraged Brian to become a qualified Youth Club Leader. An involvement of running mixed youth clubs for more than 22 years included taking young people on challenging adventures. Travelling to parts of the UK and overseas, one of Brian’s better-known youth club members included Tim Peake, Britain’s most popular astronaut.

A generosity of spirit and positive approach to people is a mindset Brian took forward into his early career. He continues this approach to this day.

Getting established …

At the age of 15 Brian commenced a five-year apprenticeship within the aircraft industry with The De Havilland Aircraft Company. He was based at nearby Portsmouth Airport and began on a starting salary of £2.50 for a 44-hour week. While serving his apprenticeship, Brian completed his training in metalworking, woodwork, machining, design engineering and purchasing. These were to play a key role in Brian’s future.Having completed his apprenticeship Brian moved on to join Vickers, Sperry Rand as a Design Engineer. Entering the field of fluid power, he was involved in the development of the first hydraulically operated vehicle mounted waste skip. This is a piece of equipment seen in everyday use.

Brian went on to join Wellman Engineering in Wales as their appointed sales engineer covering the South and West of England. This gave him an introduction to pneumatic control equipment and experience in a wide range of industries. It would also be the time he would get his first new company car.

All this was to change after two years when Brian hatched a plan for his employers. He suggested they “grow their sales within his area and to reduce their overheads” by sacking him and making him their exclusive agent. This was a bold suggestion with a wife, three children and a hefty mortgage. Wellman Engineering jumped at the chance and West Pneumatics Limited was formed in nearby High Street, Fareham, Hampshire in 1967.

Formation of West Pneumatics

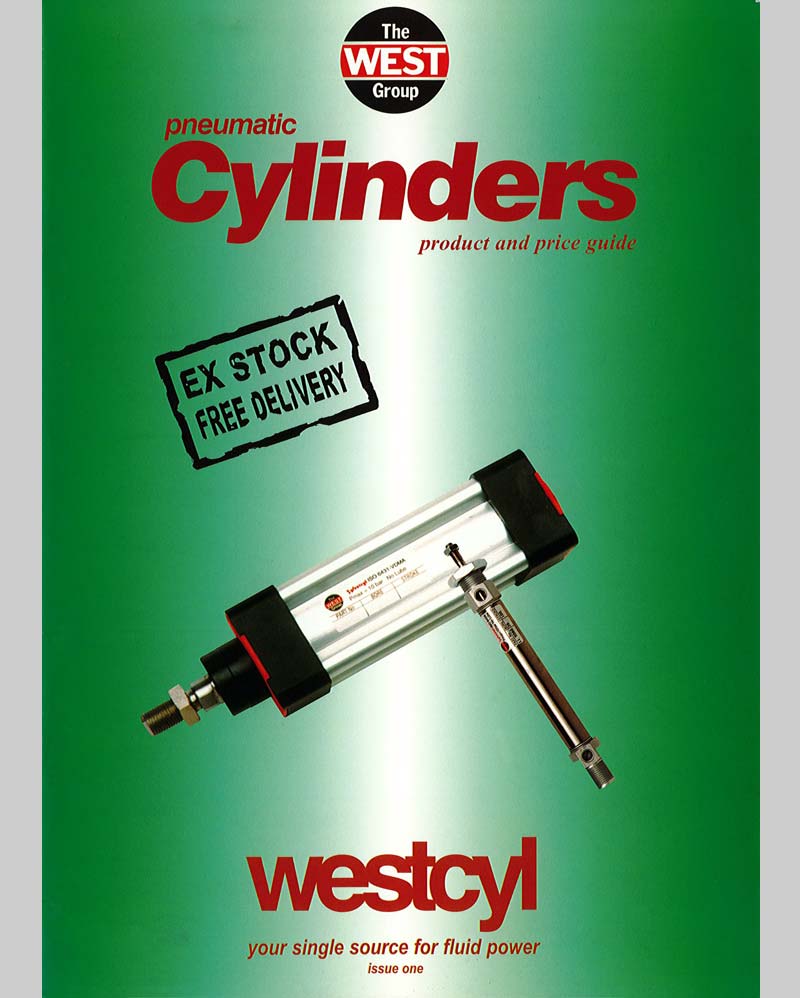

The company was originally located in a cellar complete with an artesian well below a doctor’s surgery in Fareham. Brian was quick to establish a range of agencies to compliment those of Wellman Engineering. In the months that followed, a nationwide network of stockist distributors was appointed to accelerate the growth of the company.A Fiat 500 van served as his mobile office and delivery vehicle and Brian continued to service his customer base. A key product in the company's and later the development of the group being ‘Clippard’ a worldwide leading manufacturer of miniature pneumatic control equipment. Both the West and Clippard businesses are family owned and have had close links for over half a century.

When the exclusive distribution for Clippard components became available, Brian was keen to take the opportunity. With the potential for large contracts with both Vosper Thornycroft and The Royal Navy, West Pneumatics was the chosen partner in the UK. Large orders were gained which included components going into all pneumatic control systems for the Type 42 Frigates.

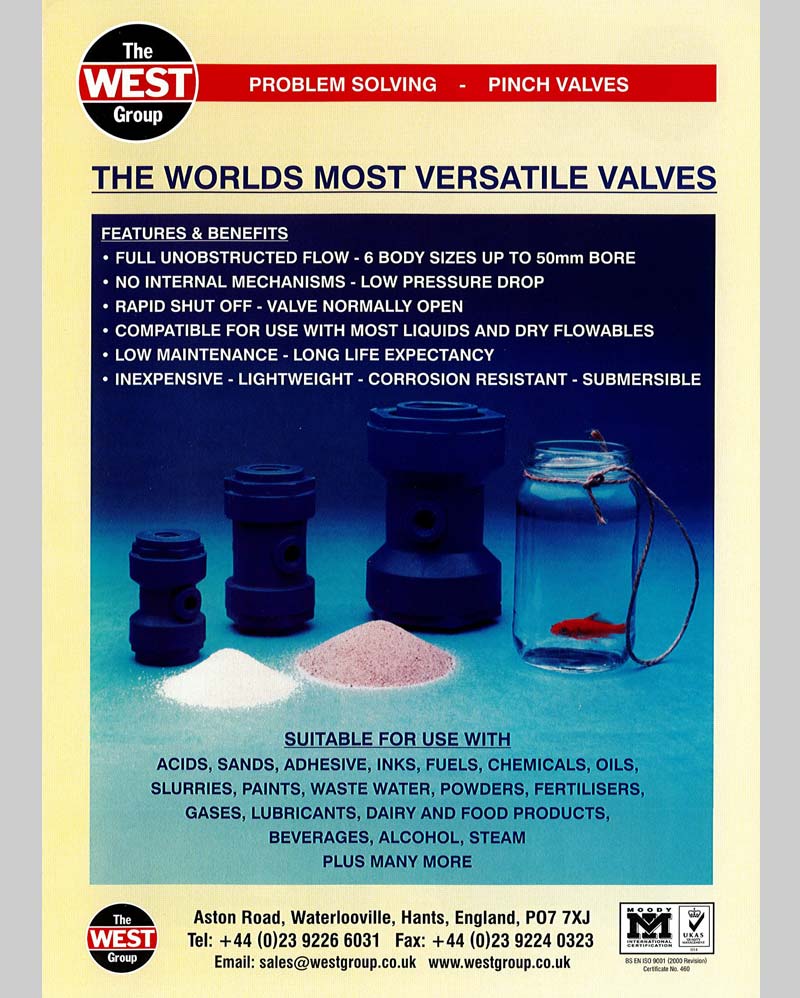

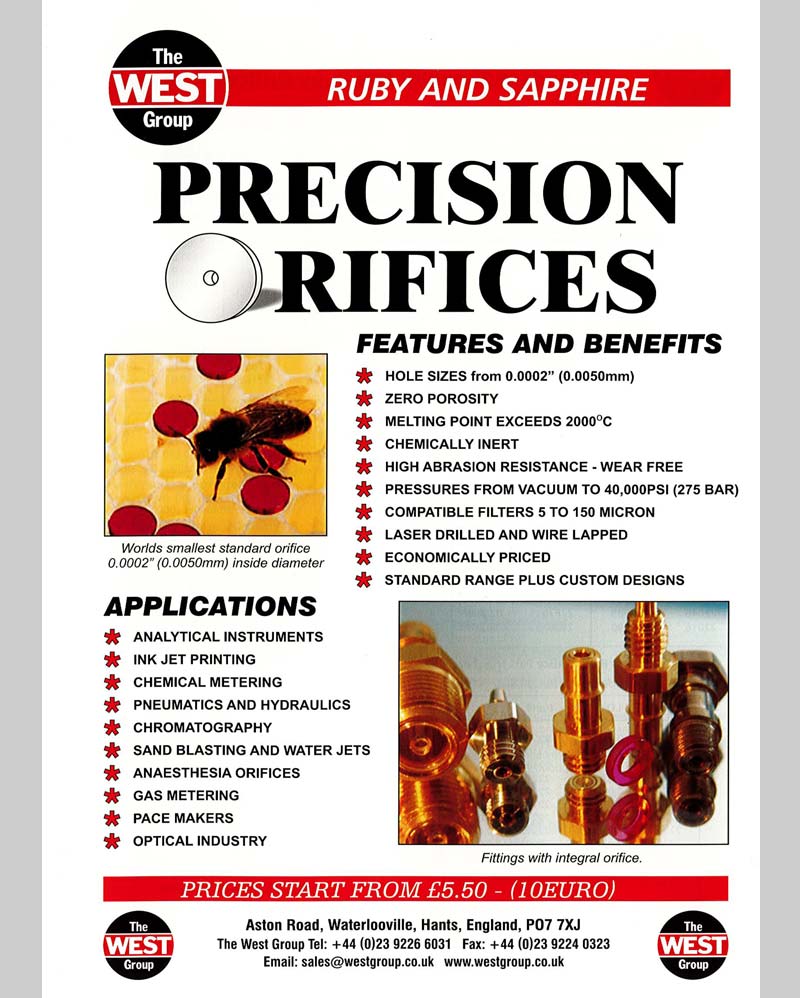

Things were beginning to fall into place. In the early nineties, Air Logic became another prestigious addition to the component manufacturers the company would come to represent. Skills learned and experience gained, Brian was able to identify opportunities and take them as they came along. His knowledge of component manufacturing, understanding their applications and ability to build relationships were the preparations that led to success.

Building the business …

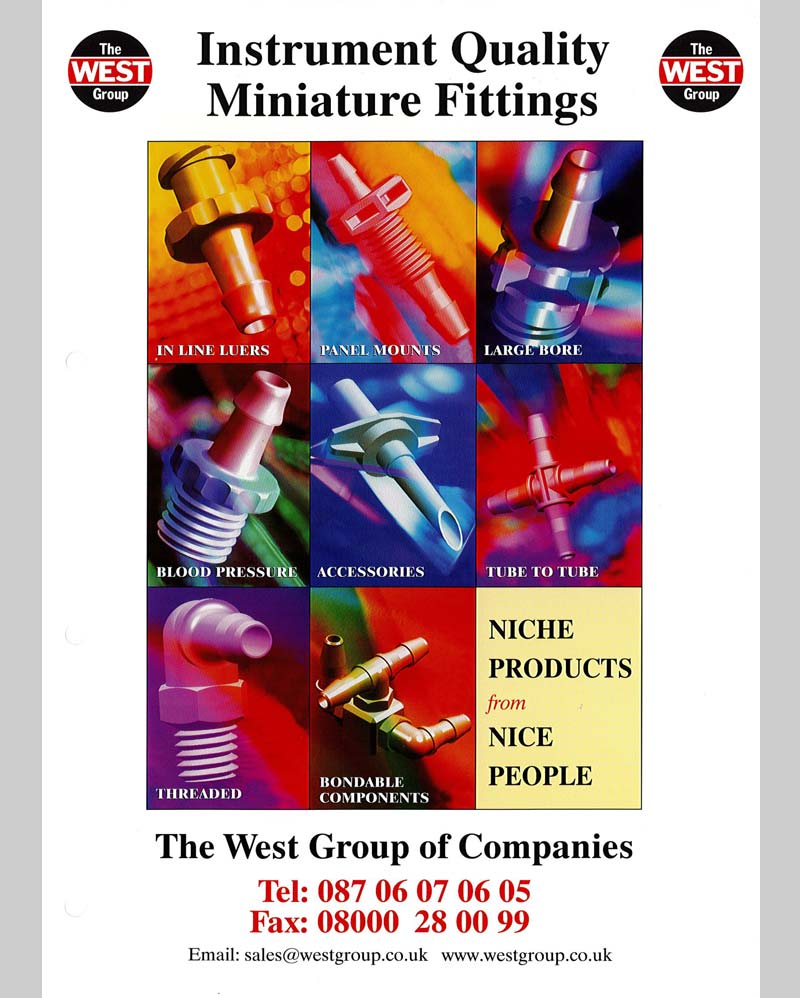

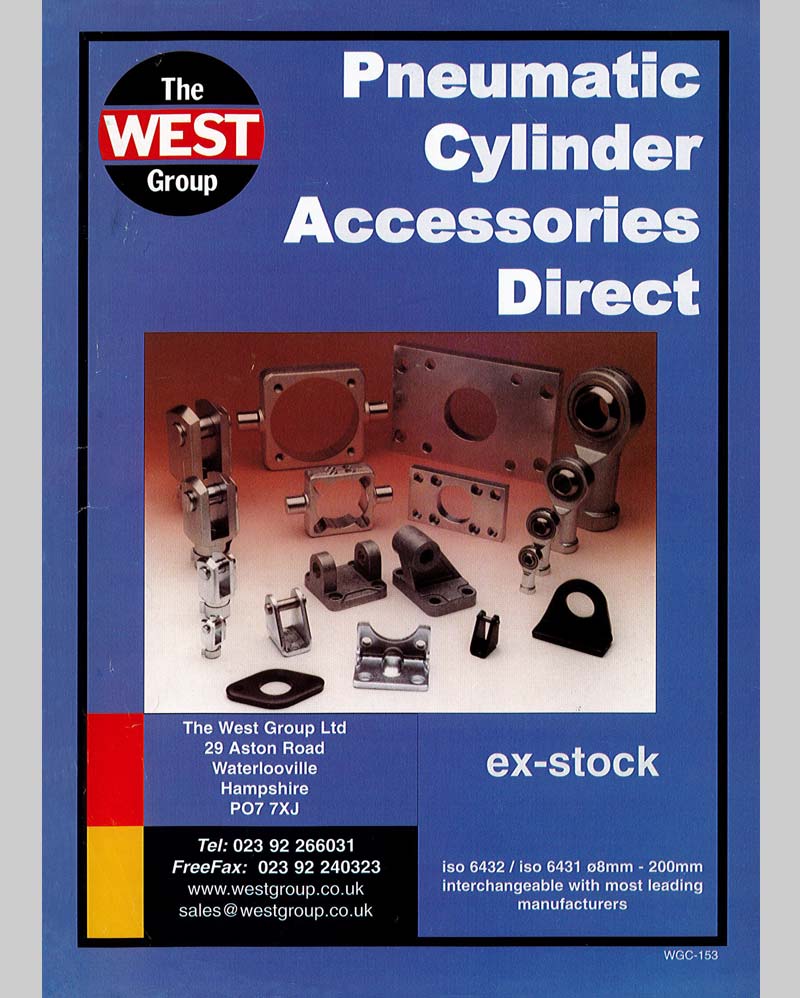

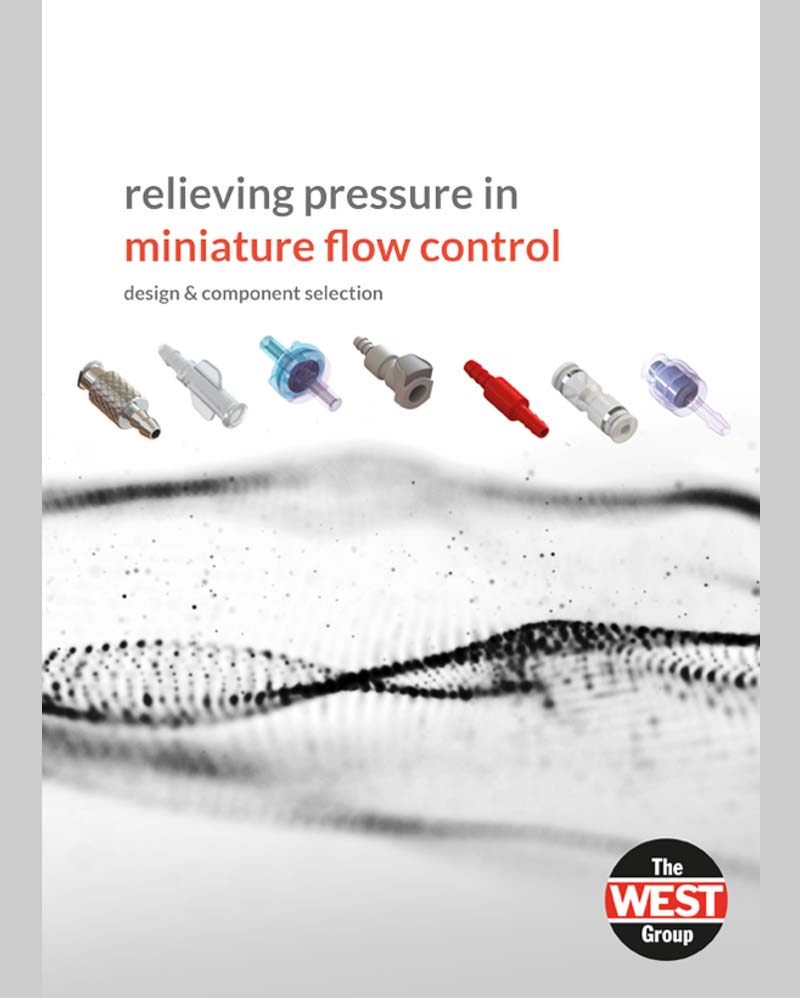

In the subsequent years, new product lines were added, and new distribution networks were established. Changes in technology and manufacturing processes presented new opportunities to offer innovations in component design and material availability. This in turn created the potential to supply into new markets.

Examples of these new markets included:

- Animatronics - Pneumatic control systems for London’s Tower Bridge

- London Transport - Driver security systems for all Routemaster buses

- Royal Air Force - Gun barrel wear measuring system for Tornado jets

- Civil Aviation - Passenger baggage inspection systems

- Film Industry - Supplying companies such as Warner Brothers with special effects for over 70 film titles ranging from Star Wars to Gladiators

Quality was and remains a driving force behind the search for component products from manufacturers across the world. Where the potential to supply was present but the component hadn’t been created, Brian looked to manufacture parts himself. He could then ensure they were of the standard and specification his customers required.

Investment in manufacturing, tooling and production was key as the years progressed. CNC manufacturing investment at the company was ahead of its time offering significant competitor advantage over other suppliers. West Pneumatics had manufacturing capability, labour force expertise and ability to supply. West Pneumatics were pioneers.

“Looking to people, looking to the future”

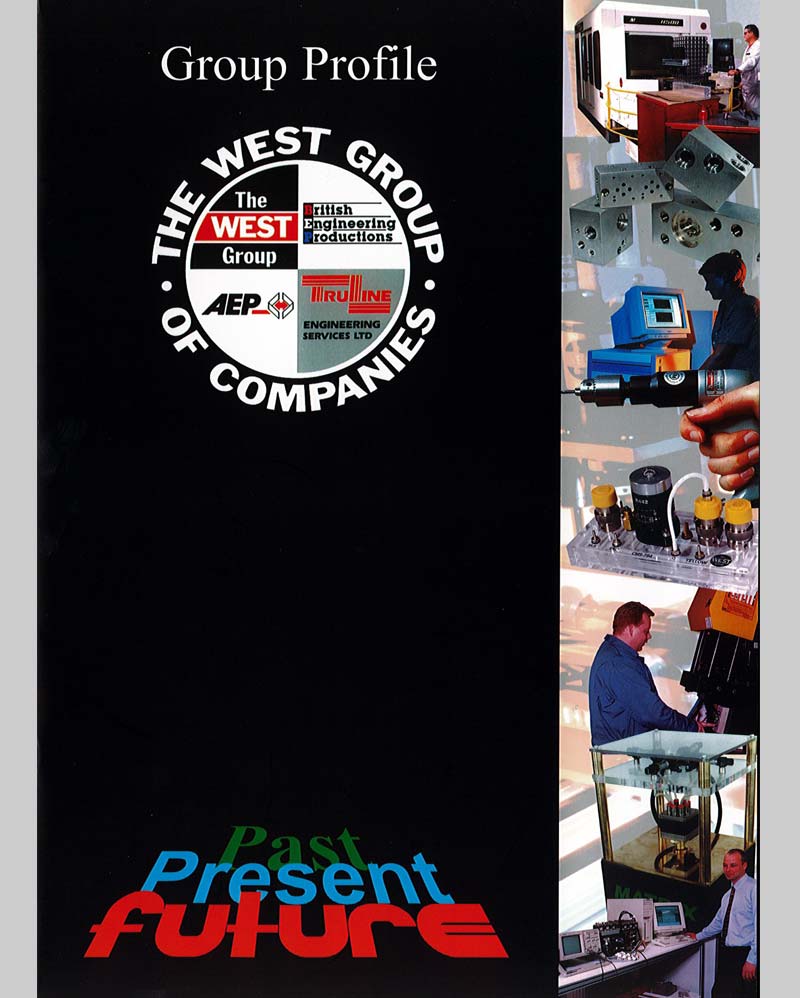

Moving from West Pneumatics into what is The West Group of Companies we know today, the company has never stood still. Brian responded to the need for equal emphasis to be placed on customer service, service delivery and product availability.

We continue to focus on our ability to achieve the highest quality while remaining competitive in the market. Our design flexibility, product performance and production capability have continued to develop into a comprehensive range of components and service capabilities. Our teams have expanded with enthusiastic and capable people working hard to achieve new ISO certification and ISO clean room production capability.

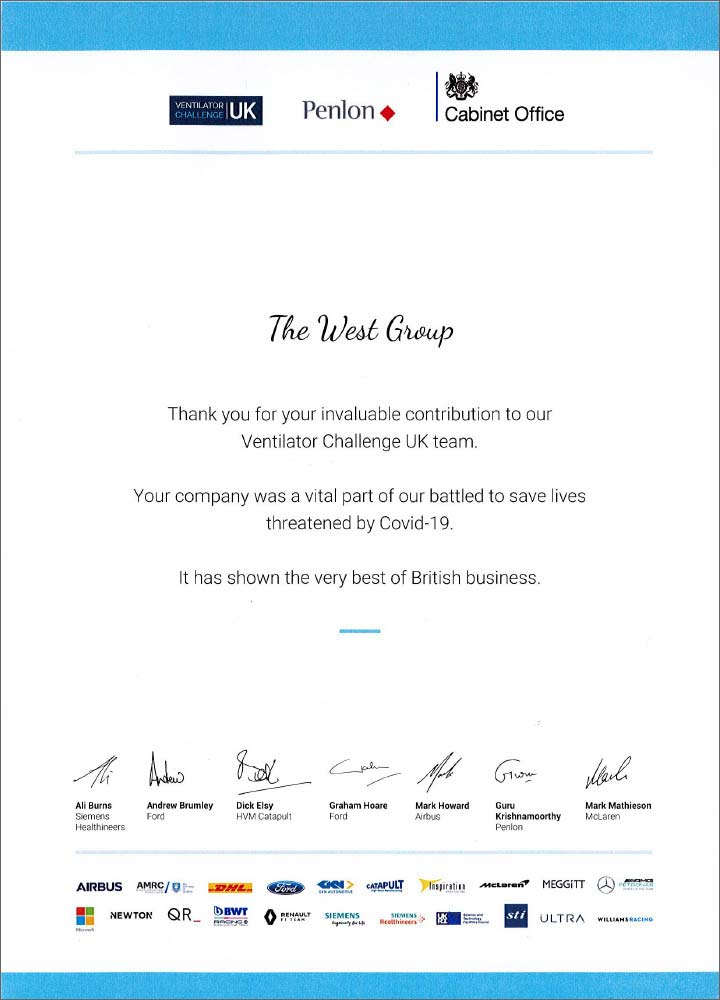

In more recent times, Brian is particularly proud of the role played by The West Group as a leading supplier of essential medical assemblies for The Ventilator Challenge. Companies and government organisations in the UK and abroad have relied upon our components in the fight against Covid19.

This new chapter in our company history places The West Group as a key contributor to British manufacturing.